What is additive manufacturing?

What is additive manufacturing?

What is system drives/mechanical drives

Mechanical drive systems are widely used in mechatronic applications in order to convert from rotational motion to translational motion and in order to match speed and torque. Seven examples of such mechanical drive systems are given in this technical note.

Types of polymers used in additive manufacturing

The following polymers can be used:

- ABS (Acrylonitrile butadiene styrene)

- PLA (polylactide), including soft PLA.

- PC (polycarbonate)

- Polyamide (Nylon)

- Nylon 12 (Tensile strength 45 Mpa)

- Glass filled nylon (12.48 Mpa)

- Epoxy resin.

- Wax.

What is known as nanomaterials?

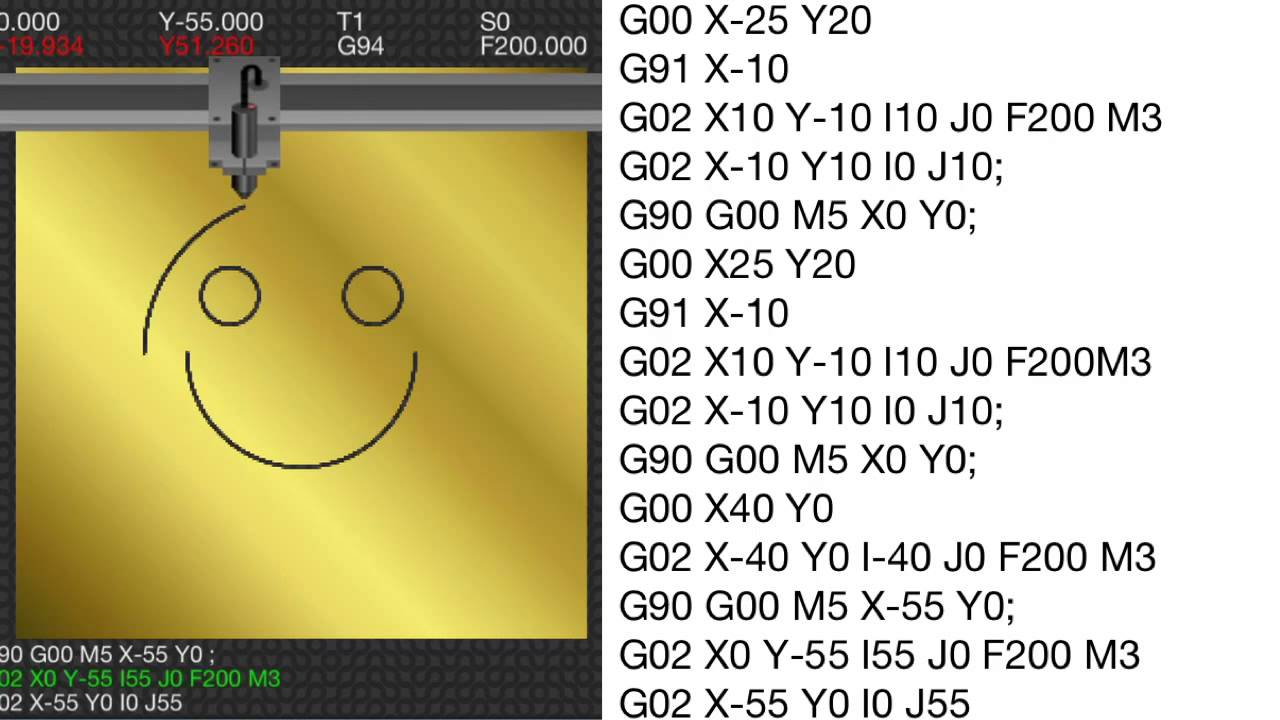

What is NC & CNC

NC machine is the machine that is controlled by a set of instructions in the form of numbers, letters, and symbols called a program. CNC machine is used to control motions of the workpiece and tool with a computer program written in alphanumeric data

What are the 7 categories of additive manufacturing?

- Binder Jetting. Binder jetting, also known as material jetting or inkjet powder printing, is among the most common additive manufacturing types. ...

- Directed Energy Deposition (DED) ...

- Material Extrusion. ...

- Powder Bed Fusion (PBF) ...

- Sheet Lamination. ...

- Vat Polymerization. ...

- Material Jetting.

What is Pneumatic and hydraulics

Pneumatic and hydraulic

What is this polymer?

What is wet chemical method for synthesis of nanoparticles?

Wet chemical synthesis is a widely used technique for growing ZnO NP solutions, in which zinc nitrate (Zn(NO3)2) and sodium hydroxide (NaOH) are generally used as the precursor reactants and deionized water as the reactive solvent.

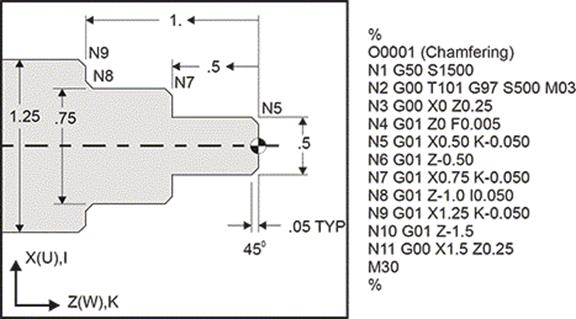

What do you mean by CNC part programming?

CNC part programming involves a series of coded instructions that are required to produce a part. The program controls the machine tool movements and controls auxiliary functions including spindle, coolant, and rotation. The instructions may include numbers, letters, and symbols arranged in functional format blocks

Is additive manufacturing the same as 3D printing?

What is hydraulic actuator?

What is metallurgy powder?

Powder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape or form (compacting), and then heating the compressed material in a controlled atmosphere to bond the material (sintering)

What is Gas Phase synthesis of Nano-materials

Nanoparticles can be prepared by gas-phase synthesis. Cooling of a saturated dense gas under specific conditions induces nucleation and growth of nanoparticles as raindrops appear in a cloud

Sample turning program

What stereolithography means?

Which are two types of hydraulic actuators?

The four basic steps to the powder metallurgy process are powder preparation, mixing and blending, compacting, and sintering. These steps have been used over the centuries to produce a variety of products

What is SEM microscope used for?

Sample milling program

What are the benefits of additive manufacturing?

- The Cost Of Entry Continues to Fall. ...

- You'll Save on Material Waste and Energy. ...

- Prototyping Costs Much Less. ...

- Small Production Runs Often Prove Faster and Less Expensive. ...

- You Don't Need as Much On-Hand Inventory. ...

- It's Easier to Recreate and Optimize Legacy Parts.

What is the working principle of hydraulic actuator?

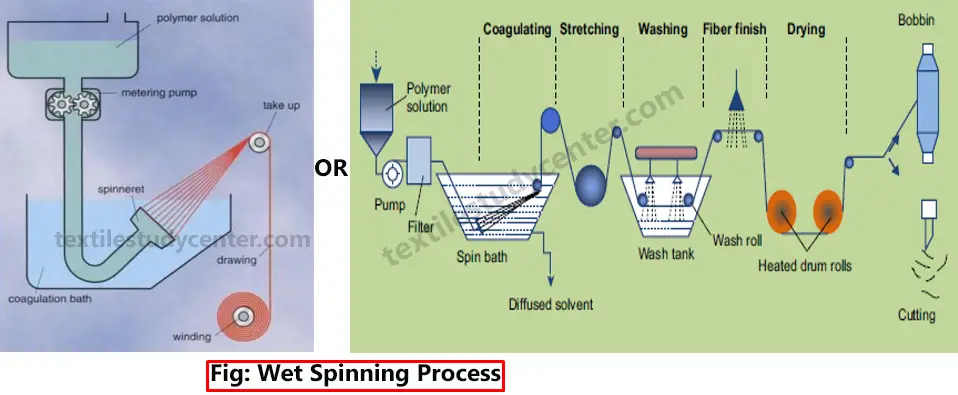

Wet spinning method

The main difference between SEM and TEM is that SEM creates an image by detecting reflected or knocked-off electrons, while TEM uses transmitted electrons (electrons that are passing through the sample) to create an image

Sample drilling program