What is true love ?

Concrete is the most widely used material in the world!

ACI ?

ASTM ?

NPCA ?

American Concrete Institute

American Society for Testing and Materials

National Precast Concrete Association

Who is our NPCA manager here at CEI ?

When does concrete typically reach full strength (in days)?

28 days.

Engineers and scientists began to understand the chemical processes involved in concrete's hardening and strength development. Around the 1920s, engineers and researchers realized that the compressive strength of concrete didn't reach its full potential immediately after mixing but instead developed over a longer period. Studies showed that concrete could continue gaining strength for weeks after pouring, but the most significant strength gain typically occurred within the first 28 days.

What is the difference between cement and concrete ?

Cement: It’s one ingredient of concrete. A binder made from limestone, clay, and other materials. (+ water = glue)

Concrete: A mixture of cement, sand, gravel, and water. It’s the finished product used in construction.

CEI = CEMENT EXPRESS INC

Great interview ?

This person has authority to cancel/stop a concrete pour.

You !

Is the pour card signed by EOR ?

What weather events should cancel a concrete pour, and why?

Rain (lightning & hail), freezing temperatures (below 40), extreme heat (above 90), high winds, snow & ice (bonding issues on formwork & rebar).

keep it simple ... look at your (5) day weather forecast ... can this pour go next week ?

rain destroys your finish and integral color turns to tie dye ... client says looks awful please re-pour it

concrete freezes during the curing process, it can lead to several issues that can compromise its structural integrity and long-term performance (ie 9% expansion creates unwanted cracks / delayed hydration / reduced bonding / less workable)

Heat, wind, Denver dry = rapidly increased evaporation to top layer and water leaches out and creates surface cracks ... again client says sorry please repour ... i cant accept/pay for this with public tax dollars $

How much water should you add to the concrete surface to achieve the desired concrete finish?

Nothing. This only generates a thin layer of weak concrete on top of the slab. What is your desired finish?

What's the minimum temperature that your sub-grade (ABC, base material) is allowed to be?

50 degrees F for slabs/pavements with sections less than 12" thick.

Be sure that is well compacted, not frozen and free of snow, ice and frost. Cover it with insulated blankets and if required use a ground thaw heater.

This common test measures the workability of fresh concrete.

What is the slump test?

What is a non-destructive test measures the hardness of concrete surface ?

Schmidt rebound hammer test

Confirm all acceptable uses with EOR prior

Why is important to know what kind of fly ash is included in the mix (what is fly ash)?

Fly as is finely divided residue made from the combustion of pulverized coal

Workability!

Class C fly ash helps to reach 28-day strength faster, but reduces the workability of fresh concrete by 26%.

Class F doesn't affect workaibility, but won't help you to reach 28-day strength faster.

Fly ash can add strength up to 90 days after pour (remember this as last resort to core b4 toss)

When is a cure compound required?

If the spec tells you, if not you can cover your concrete with watered burlap, plastic, or water ponding.

Just after having the desired finish. What is your finish (medium broom transverse; rough boat ramp; dance floor smooth polish)?

Be sure that you don't have any surface water.

A curing compound helps to avoid evaporation, keep water in the mix, and to reflect sunlight.

Make sure submittal is approved by EOR prior use.

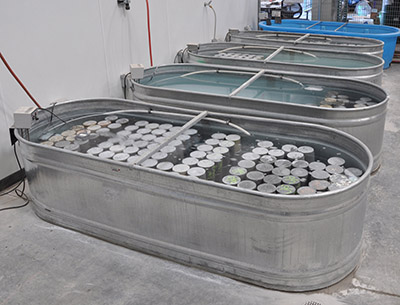

At what temperature should on-site lab Cylinders be stored until transportation?

Between 60-80 F, be sure to not use radiating heating devices and avoid having the cylinders from direct sunlight

What is the process of evenly distributing aggregates, cement, and water to avoid weak spots?

MIX!

You mix concrete to ensure all the ingredients (cement, aggregate, and water) are thoroughly combined, creating a uniform and consistent mixture that will produce a strong durable concrete structure.

During the curing process, the concrete temperature (internal & surface) shall never exceed _________ degrees F.

160 ... (& keep above 50)

When do the lab cylinders casted onsite need to be transported to the laboratory (pool or moisture room)?

24-48 hours

What is the CEI process to place a concrete order?

Job super calls BK, provide Job #, address, slump mix design, CYs, spacing, phase code, and schedule QC testing.

Be sure that you filled in the concrete info by job spreadsheet.

When is a pump truck needed / who makes the call / hourly rate / important facts ?

Limited access (truck chute or bucket cannot reach) / > 5' free fall splatter distance (segregation quality) / avoid back pain (safety) / project super / ~$500 / SW pump work order & insurance / confirm mix is pumpable /prime pump before / avoid prime slurry inside your structure /

The mixed concrete temperature shall be between _______ F and _______ F at time of placement.

50 & 90

What is a concrete field core specimen (and why does one core) ?

Actual core from your actual in-place concrete (last resort option before demo)

Locations of the cores shall be as directed by the Engineer (usually at 56-days)

Does your spec allow a correction factor (recognized damage caused by the extraction process), does your engineer agree (so 4500 psi x 0.85 = 3825 psi).

How many lab cylinders should you cast onsite?

Project-specific, the usual is 5, you can accelerate your schedule by requesting additional cylinders.

Understand the difference between QA & QC.

Never ask for field cylinders, those are out of compliance, don't waste money and time, inspectors & EOR wont accept the results

Reaching the design 28-day strength per the specs will give you acceptance and payment.

Great to have backups if 28-day results come in low ($20).

Why do we test concrete before pouring (what are the tests/what are the green light results)?

Air Content, Temperature, Slump, Weight, Time from leaving batching to empty.

Documentation is crucial; be sure to write a memo for lost time and notify the supplier ASAP (call and email)

CEI is the middle man between the supplier and tester - we need to make sure both do their job !

Who can reject a truck?

What is the purpose of the concrete mix design submittal?

Keeps CEI out of trouble (#1 takeaway today)!

Submit these to EOR ASAP (some take 3 months)

Anything special (ie fiber or color)?

That the concrete complies with your project specs, like slump, air, and w/c ratio (& EOR confirms with the submittal approval).

Be sure to look at the historical data, it lets you know how that mix behaves at different times of the year.

You will notice that as higher the temperature lower the strength.

![]()

What is the concrete curing period and why is it important?

80% compressive strength or 120 hours (5 days) / whatever is fastest.

It is the most critical timing of concrete when it gains most it's strength to ensures a quality product (i.e. baby in incubator) / remove heaters saves $$$

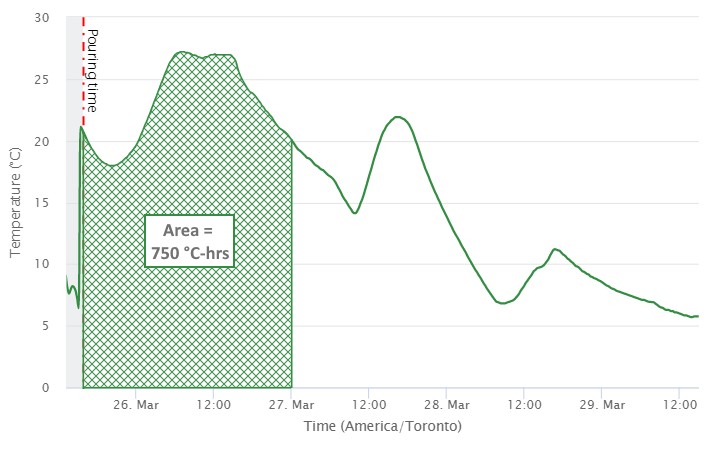

What is the concrete maturity method, and why is it used?

Provides real-time data on your concrete strength development allowing you to accelerate construction on falsework removal (80%), lifting and shipment (80%), post-tensioning cables (100%), opening structures to traffic (100%), termination of cold weather protection saves $$$, etc. Must confirm ALL acceptable uses with your EOR. EOR usually requires lab cylinder 28-day results for acceptance and payment.

If cold add $50 sensor cord = prove to EOR that concrete never froze = maybe heater went out at 1 AM (hi-low thermometer gauge shows your ambient "tent" went less than 35 degrees)

Submittal may already include the curve/equation, if not ask for it (a new mix will cost $3K and 2 months time) ... simply said "plan ahead"

https://maturix.com/by-challenges/maturity-and-strength-monitoring/

https://www.commandcenterconcrete.com/maturity-method-why-validate-maturity-curve/