Name the Japanese philosophy that focuses on continuous improvement?

Kaizen

Bonus Question: What does the "JIT" means in production?

Just-in-time

What do you call things / actions that does not add value to the customer?

Waste

Operation Time

Bonus Question: What is the name of the company in Chapter 14's case?

Quality Parts Company

What automobile company pioneered the just-in-time philosophy and will eventually be known as a leader in lean production?

Toyota

What do you call the signalling device used to control production?

Kanban

What does this symbol mean?

![]()

Customer/Supplier

Name at least 2 prominent types of waste

What is the periodic inspection and repair of equipment designed to keep the equipment reliable thus eliminating unplanned downtime due to malfunctions?

Preventive Maintenance

Bonus Question: What is the meaning of this symbol?

Ad maiorem Dei gloriam "For the greater glory of God."

What do you call something that a customer is willing to pay for in the context of lean production?

Customer Value

Name Three (3) Dimensions of Design Quality

1) Peformance

2) Features

3) Reliability and Durability

4) Serviceability

5) Aesthetics

6) Perceived Quality

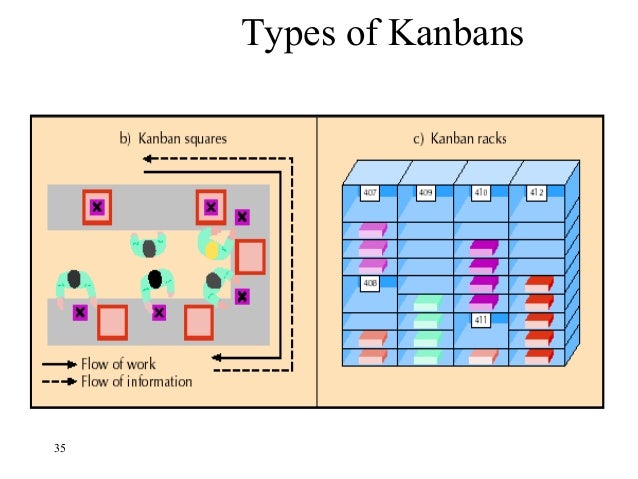

What do you call the marked spaces on a table or the floor identify where material should be stored in the just-in-time systems? It is said that supplying operations are signaled to produce more when the space is empty.

Kanban Squares

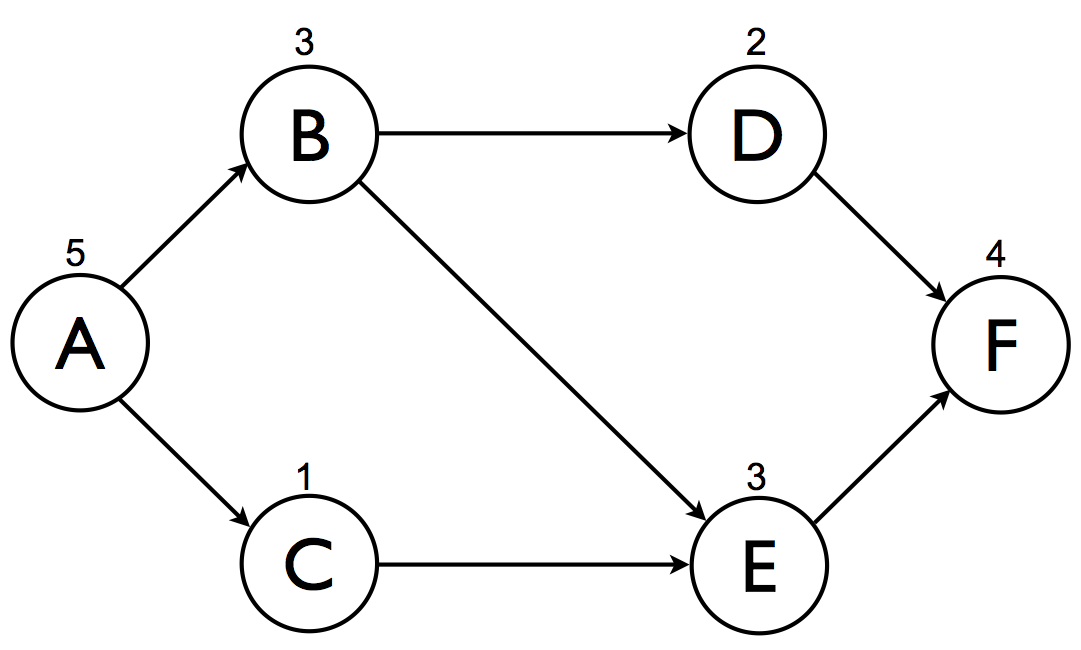

What is the critical path of the project network below?

Critical Path: A-B-E-F (15 days)

Fill in the blanks:

Value Stream identifies the ____________ and ______________ activities required to design, order and provide a product from concept to reaching the customer.

Value Stream identifies the non-value adding and value-adding activities required to design, order and provide a product from concept to reaching the customer.