What is a weld Defect?

Any flaw that COMPROMISES the usefulness of a weldment.

Slag Inclusion

What is the acronym for Direct Current Electrode Positive

DCEP

Name 2 Reasons you get porosity

Entrapped gas "gas pockets" , insufficient gas coverage , dirty metal

' & " stand for what

Feet and inches

What is a Discontinuity?

Any abnormality of a weld.

Porosity

What does DCEN stand for?

Direct Current Electrode Negative

why does my rod get stuck

not enough amperage / improper striking technique

What is .5 of a foot

6"

Can a Discontinuity be a Defect?

Yes

Lack of Fusion

What welding Procedure Is notorious for Porosity?

MIG / SMAW

Why is it important to stack welding beads properly?

To insure a solid weld

What types of material can not be cut with oxy fuel process?

NONE FARRIS METAL

Is a Defect reparable?

Yes

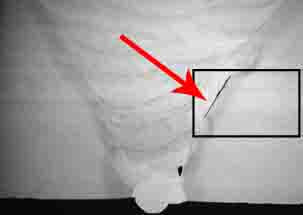

Over Lap / Cold Roll / Cold Lap

What Is the rule on selecting the strength of the rod to weld with?

Equal to or Greater than the tinsel strength of base material.

why am I getting excessive spatter.

Long arcing

what does FCAW

Flux Core Arc Welding

Can you fail a weld test if you only have Discontinuities and no Defects??

Yes, To many Discontinuities Is considered a Defect.

Name 3 Defects

Lack of "root" Fusion / Excessive "Root" Penetration / Lack of penetration

Where can I find out these things while building a project?

Rod Type

Polarity

Parameters ( Amperage range )

WPS (Welding Procedure Specification)

work piece to hot , to high of amperage , travel speed to fast , long arcing , wrong rod angle

Solve the problem on the board. What would the pipe in the middle need to be cut at?

90 degree angle is 4.25" on center